The Complete Engineering Solution for Process Equipments

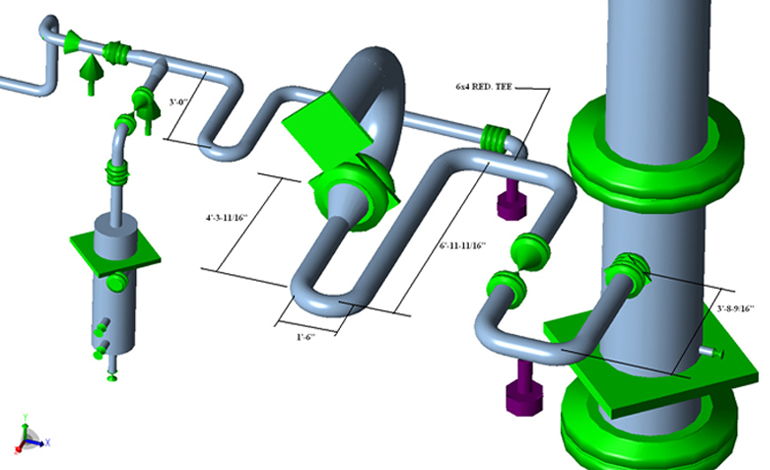

Piping Stress Analysis

We have extensive experience in Piping Stress Engineering Service to Support Oil and Gas, Petrochemical, Refinery, Fertilizer plant, Chemical Plant, Water Treatment Plant and other processing facilities.

The level of proficiencies of VES in the area of Piping Stress Analysis are as follows:

- Piping Stress Analysis and piping flexibility calculations for new piping systems in accordance with ASME code compliance.

- Piping Stress Analysis and piping flexibility calculations for existing piping systems in accordance with ASME code compliance and fitness-for-service evaluation issues.

- Design, analysis and re-rating of piping systems based on ASME B31.3. and Inspection, repair, alteration and re-rating based on API-570.

- Fitness-for-service assessment of piping systems to calculate Minimum safe operating temperature.

- Assessment of piping systems for alteration of existing pipe supports based on piping Stress for operational integrity

- Fitness-for-service assessments for piping systems to assure the structural integrity of piping for the revised design parameters.

- Failure Analysis to identify the root cause of failure for the failed piping or piping components.

- Analysis to assure Mechanical Integrity of piping systems for following type of flaws: Generalized corrosion, Localized corrosion / Thinning, Blisters, Laminations, Bulges, Gouges, Dents, Cracks etc.