The Complete Engineering Solution for Process Equipments

Pressure Vessel Code Design/Analysis

VES has extensive experience in design, analysis and review of Pressure vessels used in Oil and Gas, Petrochemical, Refinery, Fertilizer plant, Chemical Plant, Water Treatment Plant and other processing facilities.

The level of proficiencies of VES in the area of pressure vessels are as follows:

- Mechanical Design and Analysis based on ASME Boiler & Pressure Vessel Code Section VIII, Division. – 1 and Division. – 2 for Pressure Vessels as follows:

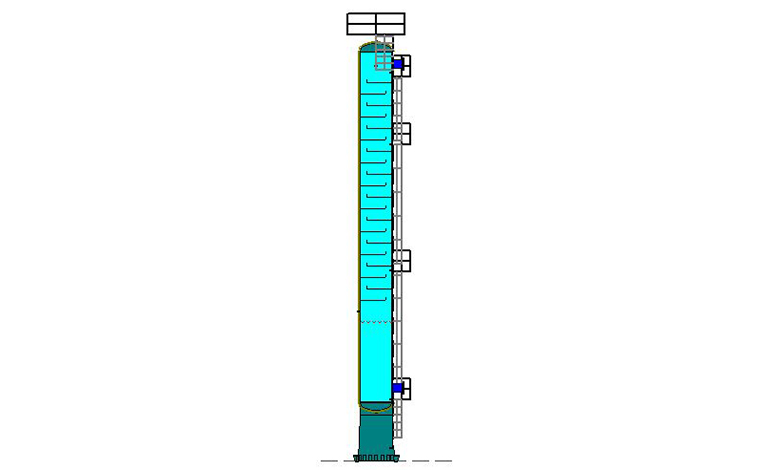

- Columns

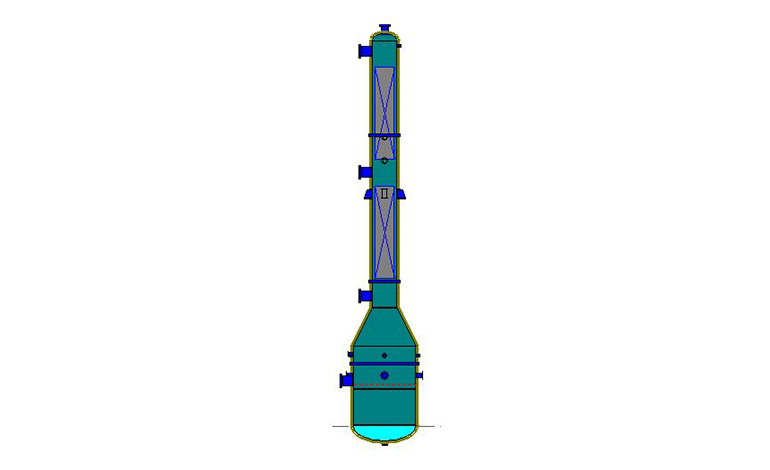

- Reactors

- Vertical Pressure Vessels

- Horizontal Pressure Vessels

- Spherical Vessels

- Buried Vessels

- Jacketed Vessels

- Pig Launchers

- Filters

- Pulsation Dampeners & Volume Bottles

- We have Extensive Experience to perform manual calculations for pressure Vessels.

- We have complete solution for the quick and comprehensive Design of Pressure Vessels as per Indian Boiler Regulations 1950. (Developed web Application www.ib-pro.in for provide a knowledge sharing platform for engineering professionals.

- We are also performing Mechanical Design as per PD 5500 Specification for unfired, fusion welded pressure vessels and EN 13445 - Unfired Pressure Vessels is a standard that provides rules for the design, fabrication, and inspection of pressure vessels.

- We also provide extensive support for PED is the European Pressure Equipment Directive 2014/68/EU and CE marking by Law.

- We also perform Finite Element Analysis (FEA) for Complex or unusual designs in accordance to Part-5 of ASME Section VIII Div-2

- Mechanical Analysis of Pressure Vessels as per ASME Boiler & Pressure Vessel Code, Section-I.

- Calculations for repair and alteration of existing Pressure Vessels per API-510 and National Board Inspection Code.

- Performing Engineering activities like Preparation of Mechanical Datasheets (MDS), technical specification, Material Requisition, project specification in accordance with industry and Client Requirements

- Analysis of Nozzle Local Load

- Analysis of Wind, Seismic and snow Load.

- Analysis of buoyancy force and blast load special for buried vessels.

- Analysis of lifting device as per client requirements.

- Preparing User’s Design Specification for ASME Section VIII Division 2 equipment’s on behalf of the Client.

- Preparing Technical Delivery condition for materials as per Client requirements and ASME Code.

- Calculation of minimum retirement thickness values for existing pressure vessels /pressure vessel components to maximize the remaining safe and useful life.

- Re-rating of pressure vessels for a new set of design parameters.

- Calculations to check the suitability of vessels for in-situ PWHT

- Pressure vessel calculations and rating / re-rating for pressure vessels that do not contain adequate design information in their old documents

- Evaluation of cracks and Flaws in pressure vessels by applying Fracture Mechanics techniques.

- Evaluation of Minimum Safe Operating Temperature (MSOT) for existing vessels which do not meet the current MDMT requirement of the ASME Code.

- Evaluation of Pressure Vessels after accidental over-pressurization

- Coordinating client, third-party Inspection Agency, authorized inspector (AI), licensed Certified (Professional) Engineer (PE) for approval of design documents, Design Verification, Validation & Design analysis

- We are also reviewing Pressure Vessels design for ASME Code compliance and Client Specification requirements.